Building Maintenance Unit (BMU) Monoblock Counterweight

Monoblock building maintenance unit counterweight makes it possible for the building maintenance unit to move in a stable and stable manner, while at the same time ensuring the safe and controlled operation of the platform. You can easily reach the high-quality and safe building maintenance unit monoblock counterweights from Greenweight.

Greenweight follows an approach that meets your needs in building maintenance unit counterweights with the options it offers, while at the same time reducing the damage to the environment.

BMU Monoblock Counterweight Dimensions

Building maintenance unit (BMU) monoblock counterweights are produced in one piece with the desired geometry and dimensions depending on demand. We can produce from 300 kg to 12,000 kg. Depending on the geometry of the monoblock counterweight, its density ranges from 6.00 gr / cm³ to 7.00 gr / cm³. Depending on demand, all necessary connection details are prepared to be installed in the MBU. Thus, the assembly to the building maintenance unit is carried out easily and without any further processing.

Get a QuoteBuilding Maintenance Unit (BMU) Filler Counterweight

Building maintenance unit filler counterweights help the building maintenance unit to operate safely and stably. You can choose Greenweight to ensure maximum safety with an environmental approach.

Greenweight provides maximum safety in building maintenance unit filler counterweights with the options it offers, while at the same time contributing to the economy by following an environmentally friendly approach.

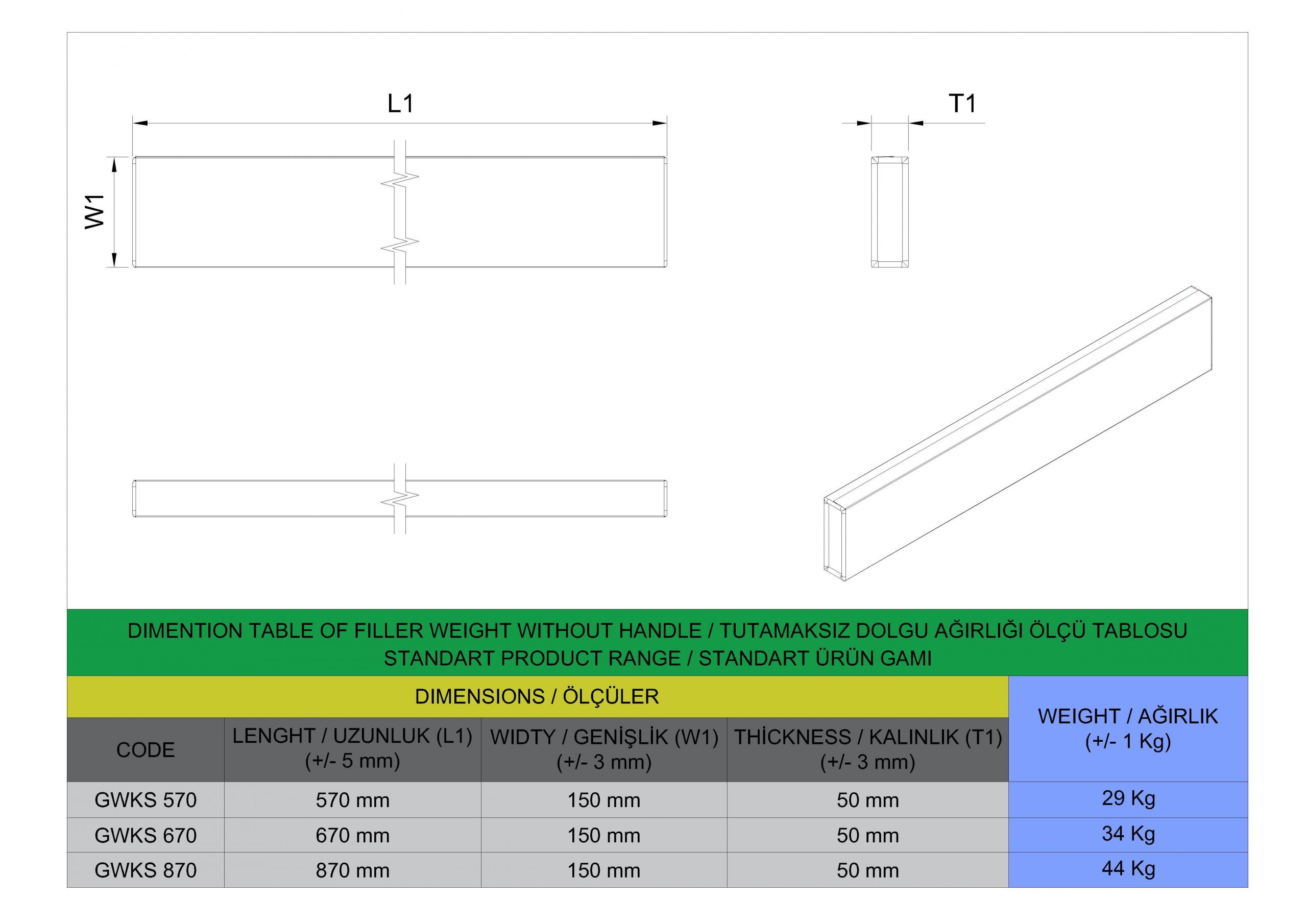

Building Maintenance Unit Fill Weight Dimensions

Building maintenance unit (BMU) filler weights can be produced in a thickness of 50 mm and 150 mm in width. Also filler weights can be produced from 250 to 980 mm in length. The produced fill weights can be easily stacked into the building maintenance unit’s weight case. The maximum weight of the filling weights is 50 kg. Filled paints are covered with galvanized sheet and does not require any paint.

Get a Quote

Fill Out the Form Now, We will Send an Offer

Frequently Asked Questions

What is Building Maintenance Unit?

A Building Maintenance Unit (BMU), also known as a Building Maintenance System, is a suspended, secure, and comprehensive access system that moves systematically on a structure, providing safe access to the highest and most complex building facades. BMUs are designed to provide secure access to facade areas of tall and complex buildings.

BMUs typically move on a carrier system permanently installed on the roofs or terraces of buildings. This carrier system controls the horizontal, vertical, and lateral movements of the BMU platform. The BMU platform allows workers and equipment to be transported safely. BMUs are preferred for their ability to perform tasks such as cleaning the exterior of buildings, washing windows, and carrying out maintenance and repair work in a safer, more efficient, and effective manner. These systems are commonly used in high-rise buildings, commercial and residential structures, hotels, and hospitals.

What Components Does the Building Maintenance Unit Have?

A Building Maintenance Unit (BMU) consists of various components that form an access system. The basic components of BMUs include:

Carrier System: It is a structural system that moves on the exterior facade of a building, controlling the movement of the BMU and carrying the working platform. The BMU carrier system is typically installed on the roof or terrace of a building and enables horizontal and vertical movements of the platform through components such as rails, cables, or telescopic arms. Depending on the BMU design, this carrier system utilizes a crane, rail system, or hydraulic drive mechanism to ensure smooth movement, reach desired heights, and access different areas of the building.

Platform: The platform allows workers to move on the exterior facade of the building for maintenance, cleaning, or repair tasks. The BMU platform, mounted on the carrier system, is designed to ensure the safety of workers during their operations. It is equipped with height adjustment mechanisms to enable workers to reach various heights. Safety features such as guardrails, handrails, and safety harnesses should be in place to secure the platform.

Movement System: It is the mechanism used to move the BMU’s working platform on the exterior facade of the building. This system is designed to control the horizontal, vertical, or complex movements of the working platform. It can consist of components such as motors, gear mechanisms, winches, or hydraulic systems.

Power Supply: The BMU power supply provides the energy required to operate the movement system and other functions of the BMU. The power supply for a BMU is typically provided through electrical, hydraulic, or pneumatic methods, either individually or in combination. The power supply should be reliable and operate continuously. Therefore, appropriate power cabling, protective circuits, and safety measures such as emergency stop systems must be in place depending on the energy source.

Control Panel: It serves as a centralized control point where the operator controls the movement of the platform. The control panel manages the operation of the movement system, provides emergency stop or pause functions, and handles other system settings. A control panel includes features such as control buttons, speed control, emergency stop, indicators, programmable settings, and automatic processing modes.

Safety Devices: Various safety devices are installed to ensure the safe operation of the BMU. These devices include emergency stop buttons, safety locks, overload protection, fall prevention systems, and emergency rescue equipment.

These components of a BMU can be customized and configured differently based on the requirements and design of the building.

What are the Building Maintenance Unit Counterweight Types?

Building maintenance unit counterweights are divided into two types: monoblock counterweights and filler weights.

Building Maintenance Unit Monoblock Counterweight

A monoblock counterweight is one type of building maintenance unit counterweight used to balance and stabilize the height adjustments and movements of the BMU platform. Typically designed as a heavy metal block, this type of building maintenance unit counterweight is placed opposite the main carrier arm of the BMU. By providing balance and stability, a type of building maintenance unit counterweight, the monoblock counterweight enables the BMU platform to move in a controlled and stable manner, ensuring a safe and controlled working environment.

A type of building maintenance unit counterweight, monoblock counterweights for BMUs are generally made of dense and durable materials such as steel or concrete. These materials provide the necessary strength to balance the weight of the platform. A type of building maintenance unit counterweight, monoblock counterweights can be custom-made in desired geometries and dimensions according to specific requirements. Optional connection details are prepared for easy installation on the BMU without the need for additional processes.

Building Maintenance Unit Filler Weight

A type of building maintenance unit counterweight, BMU filler weights refer to the components that make up the counterweight system in BMUs to ensure balance and safety. These weights are typically stacked inside the weight box of the unit and are made of dense materials such as steel plates, cast iron, pressed iron weights, or concrete blocks.

Filler weights in BMUs should have a maximum weight of 50 kg, which is the maximum weight that two people can lift at once for occupational safety purposes.

BMU filler weights assist in the safe and stable operation of the building maintenance unit. Additionally, these weights are easy to stack and place, facilitating the installation process and increasing assembly efficiency.

What are Building Maintenance Unit Safety Devices?

Safety devices in Building Maintenance Units (BMUs) are crucial components used to ensure the safety of personnel and equipment during operations. These equipment are specifically designed to minimize potential risks and prevent accidents. Some commonly used safety devices in BMUs include:

Emergency Stop Button: This button allows immediate stopping of the BMU in case of an emergency. Personnel or operators can press this button to halt the movement of the BMU instantly.

Overload Sensors: These sensors automatically stop the BMU platform when it is overloaded. They prevent potential damage to the equipment or the risk of falling due to excessive weight.

Locked Doors and Guardrails: The entrance and exit doors of the BMU platform lock securely, preventing the risk of personnel falling. Guardrails on the platform ensure the safety of workers during operations.

Emergency Descent System: In the event of a malfunction or emergency, the emergency descent system allows personnel to safely descend from the BMU platform. This system facilitates quick and secure lowering of the platform during emergencies.

Speed Control: A speed control system regulates the movement speed of the BMU. It helps operators and personnel maintain control over the unit’s movement and prevents rapid or abrupt motions.

These safety devices, along with other measures, contribute to the overall safety and efficiency of BMU operations.